I’ve printed similar objects with a different colored PLA, but I ran out of it and switched to this.

Is it possible that this could be influencing the outcome?

I have tried reducing the printing speed by 50%, but this did not seem to have a significant impact.

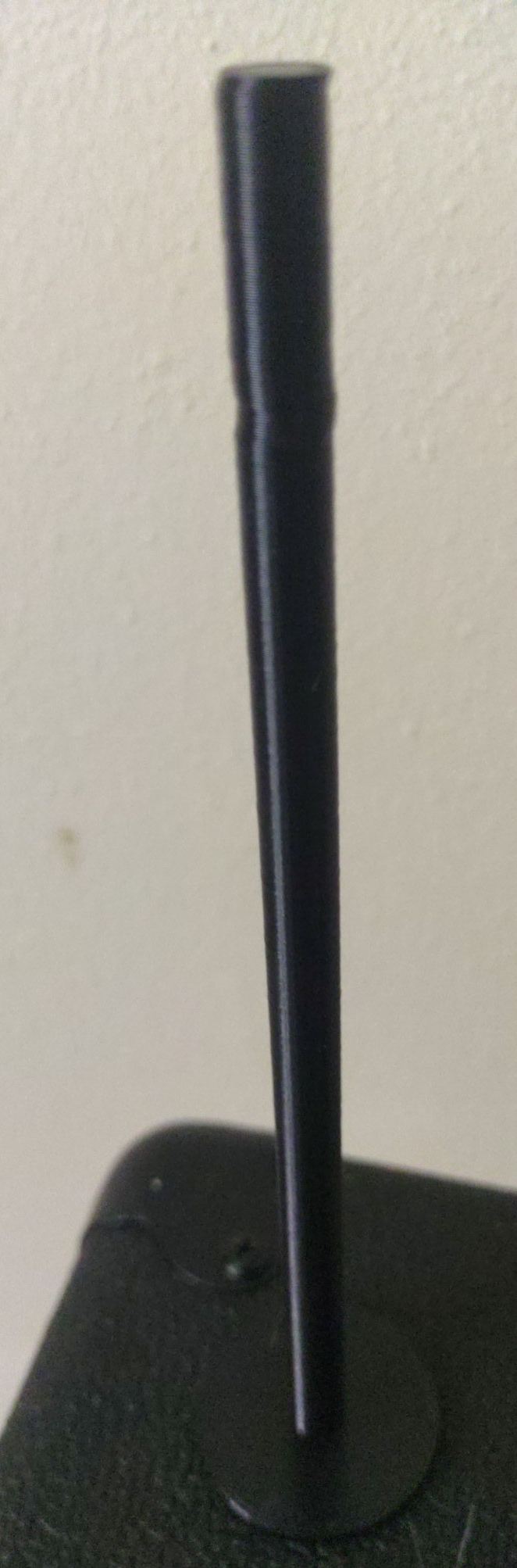

[SOLUTION] The problem was a loose screw. The offending part as well as the new result are pictured below. It’s not perfect, which I guess is actually a part of the model this time, but it’s good enough for my purposes and way better than what it was before.

I figured this out by twisting the Z-axis thingy manually all the way to the top to see if I could feel any issues. Towards the top, it would start to ‘skip’, where I would turn and pretty much nothing would happen. I assume this has to do with the lack of lube at the top because my prints rarely go that high. I checked to see if the screws were loose, and sure enough, the top one was. I tightened it up and now my printer is printing like the beast I remember!

Isn’t this kind of a torture case for 3D printing? The higher you go, the more the part itself is an unreliable surface. Even in subtractive manufacturing, any weird sticky-outy bit with an extreme aspect ratio is prone to getting snipped off to become a separate piece.

Print two cylinders half this tall. Or print one piece flat along the board. Or buy a plastic dowel.