I’m all for putting solar panels all over the place, but won’t these get dusty and oily and need loads of cleaning after trains pass over?

Also, costing €623,000 over three years sounds rather expensive for just 100m (although that roughly equates to 11KW).

Jeez, solar freaking railways.

Railways are dirty, brake dust, oil and lube leaking, human waste (from a car toilet if there is no tank).

This is Switzerland, not India. Also, it’s a test. It’s designed to find out exactly how serious those problems are and if they prevent the system from being effective.

Is this the same bunch of people that wanted to make solar roads/bike lanes too?

I could see a solar road working with some kind of passive heating medium circulated underneath but even then, the maintenance on that would be a nightmare. We can barely maintain all the roads we have already, and that’s just goopy rocks and grading.

Next test: solar panels on the bottom of the ocean.

Subnautica entered the chat.

Cause those things are similar!!

Putting solar panels between rails is as stupid as solar roadways. There is nothing to be gained and just lots of hurdles to overcome to make it (almost) as good as a normal solar panel on a roof or on a stick or on a wall.

Tell me, why on earth would you put solar panels between rails?

Edit: lot of anger here, but no answers why the panels should go between the rails, shaken daily by heavy trains. You invested in it or what?

Tell me, why on earth would you put solar panels between rails?

were just trying to find some efficiency in the space wasted by rail not-in-use. thats a lot of land. im not saying its possible, but i dont think thought experiments about these kinds of things is a bad idea

That’s like 0.00000001% of land.

There is so much unused land, why bother trains and their schedules with a maintenance nightmare between their rails?

It is just a stupid idea with no upside except the oily greasy dirty solar panels up-side that can’t get cleaned because, … wait for it …, there are Trains running over it!

I can’t fathom how such a stupid idea got more that 1 meter away from the bar counter.

I agree, there’s so much land elsewhere. Even just beside the tracks would be better than between the tracks

Because none of that unused land is set up to allow a machine to easily roll over it and automatically place/replace/clean the panels. Putting panels between the tracks means you get that for free, as the tracks are there anyway, and are already have electrical infrastructure all along their length.

The point of the experiment is to see if those benefits end up outweighing the presumably higher chance of panels getting damaged. In the worst case it ends up not being worth while and there isn’t a huge loss, in the best case we end up being able to add a bunch of additional solar capacity without having to build much new infrastructure or cover any previously unused land.

And it would be trivially easy to have a train run over the tracks to clean the panels, there are already trains which use compressed air/sandblasters/lasers to remove leaves and stuff from the rails. Just add a few more compressed air nozzles in between and boom, all your panels are now clean.

ha, ok. youll be ok. its alright. everything will be just fine.

why dont you have some nice warm milk and this cookie. youll feel right as rain.

I like the idea. Free land use. I wonder if the rails can be used as electric conductors. A special train can deploy tons per day, and could clean them regularly in a highly automated way.

Unlike roadways, they don’t carry any load.

This just shows you like the idea but don’t have any formal training in say constructing stuff.

Are you going to run 1000 volt through the rails? The rails who are bolted to the earth, like grounded? Did you think that one over :-) ?

I mean we all have thise fun ideas, and that’s actually great, because some are good even if the overwhelming numbers are not. The thing is that all the easy ones has been taken.

About the train “deploying tons a day”, where did you get that from? Also with hundred of thousands panels lining your train tracks you’ll need to replace broken ones, will you stop regular trains to do that?

And god forbid one rattles loose and wrecks the underside of a passing train as it gets sucked up by the wind from the moving train lol.

It’s just not a good idea.

I don’t know about the practicality of rails as conductor, but it wouldn’t have to be high voltage.

About the train “deploying tons a day”, where did you get that from?

article said special train could deploy 1000 panels per day.

They make a better roof over the tracks that the train passes under than being on the ground. They could even be tilted to better face the sun.

This but for cycling pathways in cities (no cars allowed).

There are “defect detectors” on railways to warn engineers when their train has a chain, air hose, etc dangling and dragging along the ground - which is a potential for accidents of many varieties.

I guess now you can replace that with trains that automatically stop when the Katamari of dislodged solar panels eventually builds enough mass to force a car off the rails.

Surely the maintenance of such problems would be very easy though, given it’s already on rails you could run a carriage with washing machinery underneath to clean these occasionally. Interested to see how serious the deterioration over time is due to the grime.

Don’t forget that maintaining all this means people working directly in the track trying to fix high voltage electrical issues while dodging trains and hoping dispatch doesn’t forget about them, or that ballast(the gravel between the ties) needs to be renewed regularly, much less all the things like realignment and rail grinding that use specialized machinery that needs to go right in the space between the rails.

This means that those panels are going to have to be removed and installed often, at best vastly increasing wear and tear on them as compared to a fixed installation, and adding the risk that a failure in the pickup/deployment process could scrap a significant number of panels if not caught immediately.

Or that the hard part of installing solar panels is the wireing, inverting, and grid interconnection, all of which are just made that much harder by having to have electricians doge trains.

Look, if there really is absolutely no possible available space, like say desert, farmland, roofs, parking lots, yards, fences, well just put the panels up on a simple metal frame over the railway, maybe even integrate the catenary hangers if your feeling daring.

This at least provides some benefit to running the railway by keeping snow and leaves off the tracks to some extent while also keeping the panels out of the way of running the railroad.

Yes because they never close the lines for maintenance or repairs

Typically not for more than a few hours when it comes to in service track, and management actively despises those maintenance windows even when it’s necessary to the continued existence of the track, much less a third party startup.

There is a reason why even when the entire track and ballest on a main line are wiped out by a natural disaster it will usually be up and running again in a few days.

As such I would expect any non experimental contracts between the startup and the railway to come with not insignificant financial penalties if they interfere with service, such as requiring a shutdown of the track for repairing the panels being subjected to said harsh environment, thusly either delaying fixing the panels for the next scheduled major maintenance window in a few years or else like most railway inspections doing the work an an active line between trains.

When the competition is a large open field of dirt that can be accessed at any time for maintenance, can leave the panels up for decades, is centrally located for easy grid access, and requires far less frequent cleaning, I just don’t see how this startup is going to outperform.

you have to keep the panels clean in order to work. this is not a great position to do so

Hopper cars lose coal and ore all the time

This is Switzerland, outside of a small number of corridors the majority of tracks see virtually nothing but passenger trains.

Trains with hoppers are not present on all railways though.

But these solar panels will be present on those with hoppers.

i’d be more worried about about smudgy stuff. they get dusty, then it rains and the panel is covered in a film of dirt. bird shit on solar panels is already plaguing home users

could trains have some kind of mechanism that might help? physical contact seems too much, maybe a blower?

I’m sure enough air is moved simply from the train moving by, but there will probably still be rocks and stuff flying around

won’t really help against bird poop and such

have we run out of convenient places to put panels? that’s news to me, last i checked we still had a hilarious amount of free roof space and stuff like parking lots where we can just slap up the panels.

Putting a solar roofs over any open-air carpark you happen to own is just a hilariously easier option. Hell, you could erect these OVER the train tracks.

https://greenox-group.de/photovoltaik-carport/ (Article is in German, but it’s really more around the picture)

According to a completely un-sourced picture I found online, one carpark (in the USA) is typically around 5.5 x 2.6m, so if you had even 50 carparks on your site you could have ~715 square metres of panels. More, if you figure a way to cover the aisles between the rows of carparks too.

At the top end of all applicable figures (panel efficiency, solar irradiance, inverter efficiency), that could net you ~160kW at solar midday.

Now on the other side, standard-gauge railway is around 1.4m wide, and maybe you could cram a 1m width of panels between the rails.

That sounds like a lot - 1000 square metres per kilometre, and there are thousands of kilometres of railway lines out there - but it’s harder to install, harder to service, gets dirty faster, is liable to get damaged, and now you have to figure out how to extract power from somehing a kilometre long, instead of an area that could be a square only around 35m (~115’) on a side (for the above 50 carparks).

I know which one of those I’d want to run the cables for.

As has been pointed out many times when this dumb-ass idea comes up, only once you’ve exhausted every other possibility (carparks, rooftops, putting panels ABOVE roads/rivers/canals/cycleways/railways) and have literally no other viable installation locations, then we can talk.

My dad worked with a guy who is designing a system like this and it makes all the sense.

-

you shade the parking spaces

-

you absorb less heat into the ground than tarmac

-

free energy

-

direct panel-to-car charging for EVs

-

solar canopys are actually quite expensive. Needs a very sturdy structure to hold panels high up and deal with wind loads. Solar panels are getting so cheap, that it becomes very reasonable to lay them on the ground instead of optimal angles, higher up.

Why not on the sides of the railroad? Often, there is significant free space on both sides of the track.

I was about to comment that it makes more sense to put panels in open space, but looking into it does appear some numbers crunchers did the math on efficiency gains from being able to swap old panels with a dedicated machine on the rails, versus the other option.

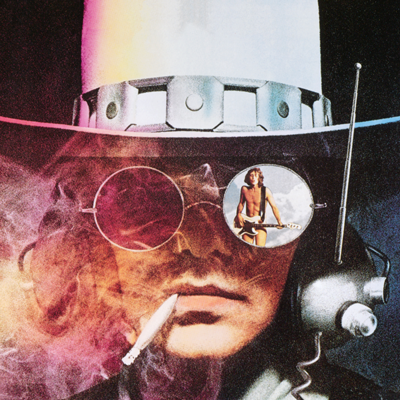

Solar freaking railways

I expect it would turn out like this:

And here’s a Hacker News thread discussing it

i think they’ll crack from the vibrations, or to avoid that they’ll need to be built a lot sturdier than normal.

In which case just make the cheap version put them on top of buildings, in cities, near to demand; like everyone with a quarter of a brain has known since their invention.

Don’t install sensitive/ fragile equiipment in dangerous places near massive energetic machines uness it’s neccesay for those machines or there is really no where else to put it.

Can I get 60 grand to shove a solar panel up my arse as an “experiment”? Maybe some of these dumb experiments will help figure out a way to manage all the challenges of idiots who have more money than sense - that might be worth it.

how about those flexible printed ones? They’re protected from the wind by two metal barriers

Yeah but they have thousands of tons of steel going overhead and rocks and dust all around. I don’t really see the advantage compared to a solar farm or a roof where they’re easier to set up and maintain

Fair point, that won’t help

An idiotic idea which will go nowhere just the one about putting PV modules on road surfaces was.

It seems like it a bad place. It would probably shorten the panels’ lifetime, and maintenance would be tricky without interrupting train traffic.

Let’s work on putting more solar panels on schools, malls, parking lots, train stations, and any structure with a large roof.

The 600000 € probably include the development cost. Thus, on a larger scale, the cost per unit length will decrease significantly.

True, but it still seems rather excessive…

That’s like 1/7th of the cost of a single passenger car. I’m sure they can easily afford to take that hit if it doesn’t end up panning out.

2 axis solar trackers are much more efficient, but fixed installation beats them in cost/W in many cases.

Any solar installation gets dirty, the question is do you save labor/equipment cost by having them cleaned by a single solar cleaning train, vs. tons of workers or automated brushes cleaning a large open field installation. Do you need to do cleaning passes after every train? Daily? Monthly? Yearly? Is there an intersection of efficiency loss and cleaning investment that is profitable?

If you could install and maintain them in a fully automated way with just a few specialized trains, I can see why it might be an attractive idea. Question is how automated can you make it really? Do you need to fasten the panels down? How do you tie them into the grid?

If the savings on installation, maintenance and cleaning offsets the loss in revenue from the suboptimal placement and dirt, it might work.

I could see this working out if deployed on large scales, where the up front investment of developing all the specialized process and equipment, like trains, becomes a small part of the cost.

Any such proof of concept installation of an unproven technology will be more expensive than if you really deploy it at scale.

If rail didn’t exist today and we had to develop the first train and track and all the necessary infrastructure around it, the first 10km would be ludicrously expensive and would never pay itself off compared to the existing road network or shipping routes.

It’s a finetuning and risk taking problem. Does the idea make sense in a vaccum? And does the idea work in competition with existing solutions? Is anyone willing to invest enough money to make it competitve?

I hate it when extremely complex multi-variate problems always get judged based on one or two possibly negligable variables because of ignorance or intellectual laziness. Sometimes you can successfuly jugde things this way, yes, but rarely are things that simple.

Also, costing €623,000 over three years sounds rather expensive for just 100m

It’s hugely expensive, but I expect most of the cost to be in the wagon that lays panels down and picks them up - and could hopefully service a big stretch of railway (if it works). That kind of systems will cost a pretty big penny.

I doubt if this project will “fly”, however. A totally horizontal solar panel at ground level is a far cry from producing energy efficiently.

Even if not between the tracks, aside the tracks there is quite a bit of empty space. That space gets a lot less of a hard time from the trains rolling by

Trains drop metal bits pretty often too. A lot of these panels will get shattered

What’s the plan for when people start stealing the solar panels? Good luck trying to stop people

The plan is the same for people stealing spikes and rail to sell as scrap: Railroad police don’t fuck around.