When I started soldering everything was big and had leads that went through holes in the board. You inserted the leads, bent them over to hold the component, flipped the board over, soldered everything, and trimmed off the excess leads.

Now I’m soldering things down to 0402 SMDs (1/4 the size of the smallest component in the picture) using a needle point soldering tip and a microscope.

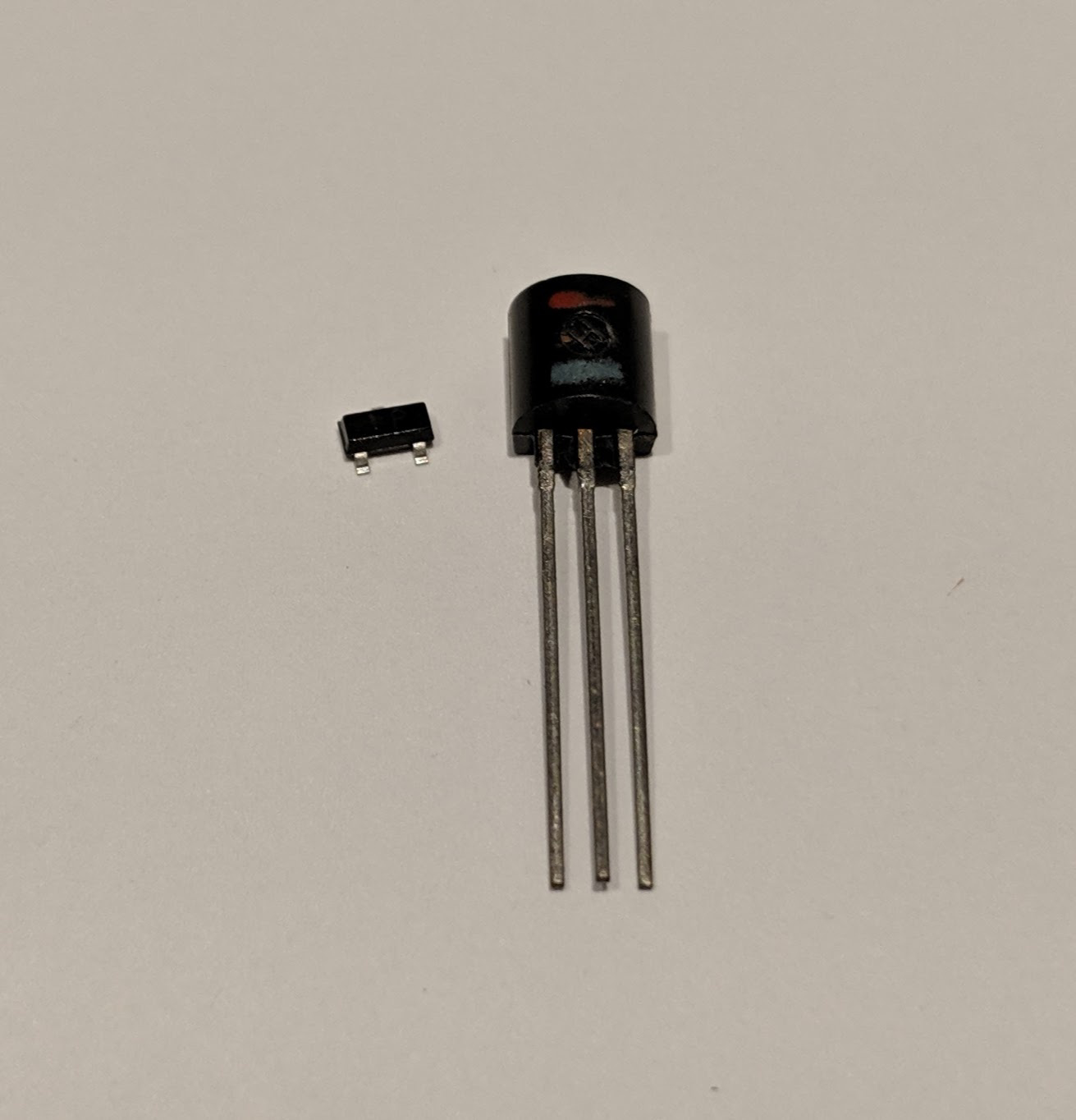

A pair of 2N2222 transistors, one SOT23 and one TO-92.

This reminds me of high school. I took an electronics course and we had to hand etch our boards with tape and acid.

Oh man, I remember doing that. We had rub on transfer traces and pads that we could apply to the board before etching that did a good job. I used to buy those at Radio Shack.

My friends, the ones I take in the microscopic soldering jobs for, have a small CNC mill that they can use to mill boards. That’s very cool.

I miss radio shack ! Yeah 2003 baby hah. I wish I could do microscopic soldering

I bought a Olympus SZ40 on an arm for $200 from a microscope shop in Montreal. It’s the best $200 I’ve ever spent. It makes soldering so much easier.