When I started soldering everything was big and had leads that went through holes in the board. You inserted the leads, bent them over to hold the component, flipped the board over, soldered everything, and trimmed off the excess leads.

Now I’m soldering things down to 0402 SMDs (1/4 the size of the smallest component in the picture) using a needle point soldering tip and a microscope.

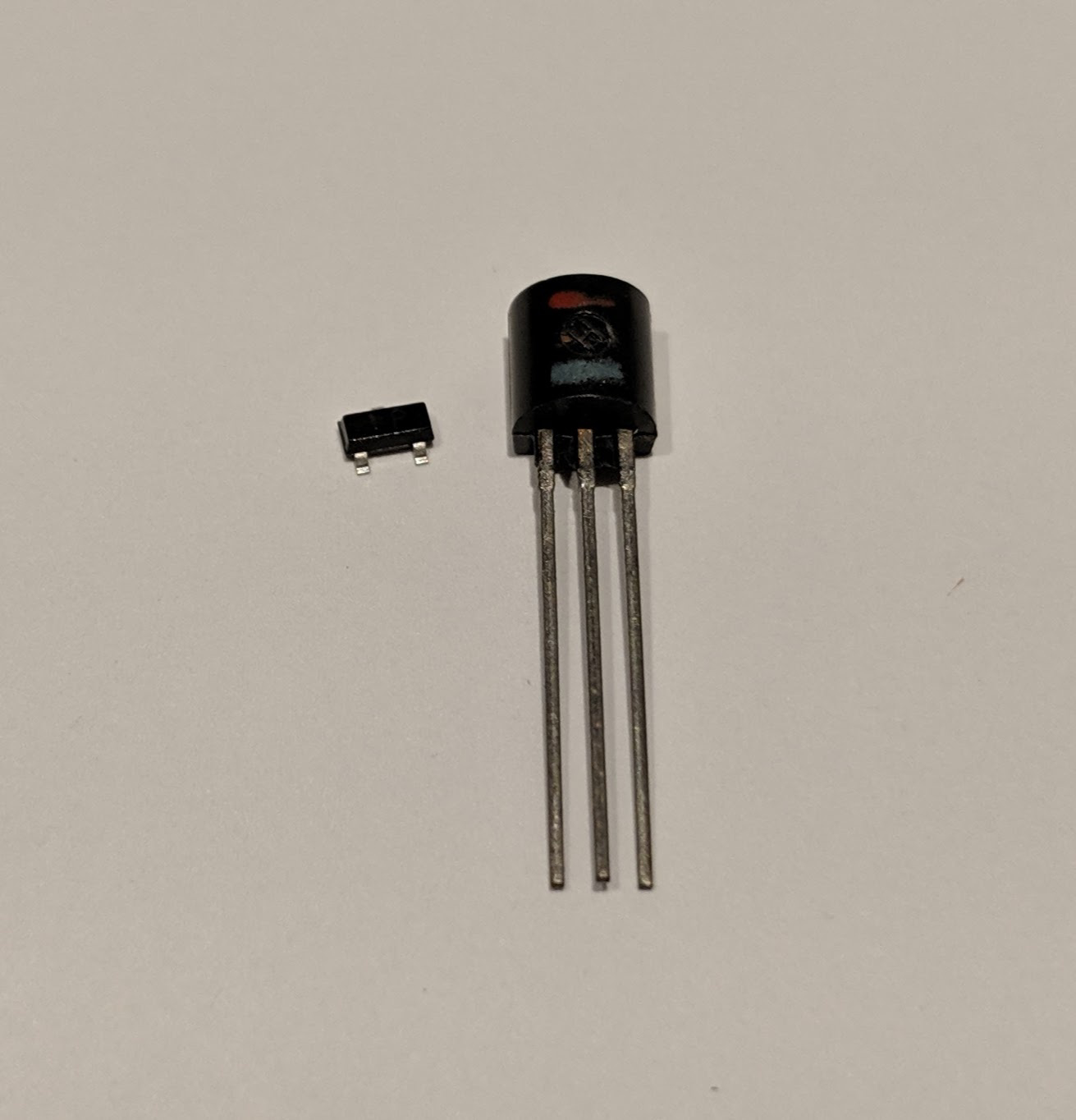

A pair of 2N2222 transistors, one SOT23 and one TO-92.

I end up needing a bunch of extras for 0102 components. If I don’t get contact with the solder blob before relaxing my grip on the tweezers, hot air blasts them away into oblivion.

That sucks. I’ve never gone that small. I ordered 0402s the first time I ordered SMDs. Now if I’m going to be soldering by hand I always order 0805s. Even those get flicked or blown away maddeningly often.