When I started soldering everything was big and had leads that went through holes in the board. You inserted the leads, bent them over to hold the component, flipped the board over, soldered everything, and trimmed off the excess leads.

Now I’m soldering things down to 0402 SMDs (1/4 the size of the smallest component in the picture) using a needle point soldering tip and a microscope.

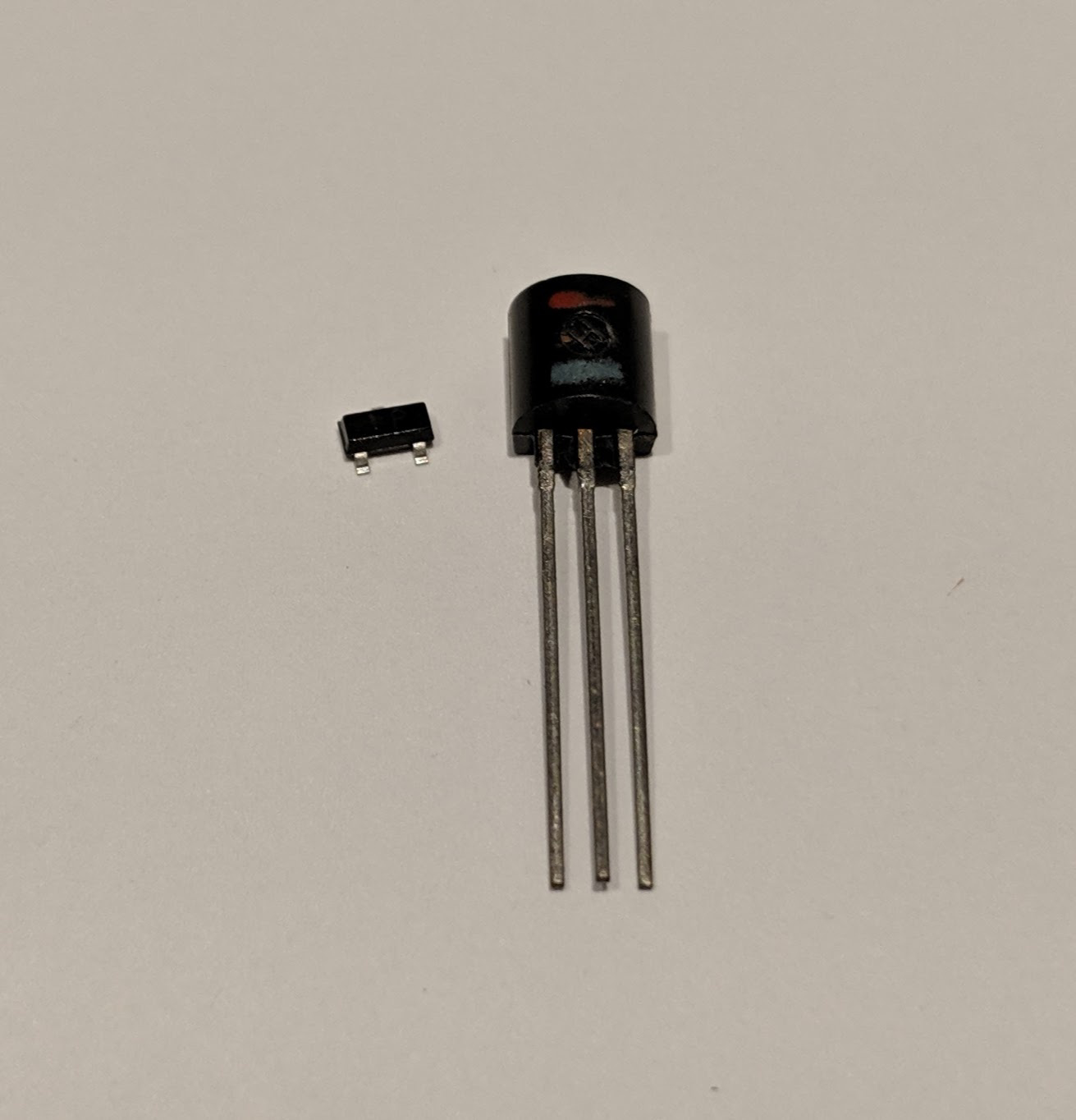

A pair of 2N2222 transistors, one SOT23 and one TO-92.

Tweezers tip irons and/or a hot air unit saves some of the headache. Now if only the ol’ eye balls functioned like they used to back in the day… maybe the eyes where always bad and the writing on the through holes was just bigger haha!

Hehehe. I got a microscope a couple of years ago. It’s an old, formerly very expensive optical binocular. An Olympus SZ40 that I bought for $200 from a microscope shop in Montreal. I can’t live without it now.

The next thing on my list is a pair of tweezers for my Hakko. After that I’ll start looking at hot air options.