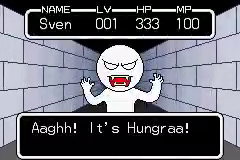

Damn Judi. I mean yes, but I wasn’t expecting THAT face to suggest it…

My wife cuts food with her own sewing scissors. I never realized i was living with a crazy person until this point. (Ok maybe i kinda did)

As a seamstress: fukkin’ yikes.

If she only sews casually, that would make sense, though. But it still gives me the jibblies.

Yah it’s like once every few months or so to fix up a new outfit or something. It just happens to be close to where the upstairs TV is so she’ll grab them if she needs some while we’re eating while watching a show or something. Then they end up in the utensil drawer and I’m usually the one that finds them and furrows my brow a bit before putting them back by the sewing machine

So I am definitely the odd person in the sewing world who cuts everything with my scissors. I’ve been a sailmaker for 30 years and we cut paper, Mylar, Kevlar, carbon fiber, fabric (of course), rope, tape, adhesives, you name it. I’ve been using the same pair for 20 of those 30 years as well. We do get them sharpened but not all the time.

Dyneema is the one thing that will mess up your scissors though. My buddy at work had a dull spot on his that wouldn’t sharpen from dyneema webbing. We ended up getting a special pair for that and Kevlar, with micro serrated teeth.

I will say though that a person’s scissors are sacred, you don’t touch another sailmakers pouch and tools. What they do with them is their business, use your own tools.

That extends to all tools in my opinion.

Don’t borrow someone’s tools without their express permission, and don’t lend someone a tool unless you either know what they’re doing with it or you don’t care if it gets damaged.

Yup. I hired an apprentice once, and the first few days every time I’d come into the shop my pouch would be either missing or emptied and I’d have to run around finding my tools. Did that twice and was like your first job is to make your own pouch and then got him his own tools. My fault really, I should have done that right off the bat.

Mind if I bug you with questions about sail making? That sounds like a super interesting job!

For sure! Though I apologize if I don’t answer right away! I will answer though.

How do you get into a job like that? I figured they would mostly be made by machines nowadays.

What’s the biggest sail you’ve worked on?

Best/worst material to work with?

What kind of equipment does your job require?

You mentioned a knife but I’m guessing it’s not a common knife. I’m imagining more of a hook shaped blade to pull easier, but would love to know if I was wrong

I’d like to tag on and ask if op plays Enya - Orinoco Flow every time a sail is completed.

THEY DAMN WELL BETTER!

Of course! That’s during the offering to the wind gods.

deleted by creator

Thanks a ton for the answers!

I’m honestly unsure where my brain got the knife thing if I’m being honest.

One more question for you if you don’t mind -

How’s kevlar to work with?

Haha, my brain does the same thing all the time.

Kevlar is a funny one for me as I’m now allergic to it. Yay occupational disease! If I have to use it for a quick job it’s fine, but anything longer than an hour I get what feels like a sunburn. Usually on my arms and cheeks, basically where I touch when I push up my sleeves or whatnot. Doesn’t get red, just feels like a bad sunburn. One of the ways it’s used is in big rolls with an adhesive backing, for patches. So we’re not really sure if it’s the Kevlar or the adhesive, but I can use any other product with an adhesive back and it doesn’t happen.

Anyhoo, Kevlar is really tough, so it can be a pain to cut. That toughness makes it great for backing patches or chafe patches. On Genoas we’d use it to make spreader patches. It’s really only used like that on laminate sails. Though I’ve seen Kevlar leech line used on Dacron sails. Another common use is in kayak hulls along the keel for abrasion resistance. It also has a very high melting point and will char more than melt, which also helps with chafe. Its UV resistance isn’t the best so it will deteriorate over time. But racing sails don’t last as long as cruising sails so it evens out. You can recognize it on a sail as it’s a golden yellow.

Edit: I think it’s fallen out of favour over fibers like dyneema and carbon. I haven’t been in that part of the industry in a long time.

The fibers and technology in racing sails are pretty crazy. There’s some neat videos online if you want to dive a bit deeper into it.

A kevlar allergy is definitely an interesting one!

I gotta ask what you mean by patches. Judging by the fact you seem to mostly work on racing ships and other very expensive sailing ships, I’m guessing you don’t mean patches in the sense of filler material to fix holes?

Hey did you follow the americas cup this year?

What did you think of the wingsails / twin skins / no boom configuration?

Hi! I didn’t at all tbh, but your question just made me go on a deep dive looking at the boats. So crazy! I’d seen pics of them but hadn’t looked real close. I have to say, it makes sense for the racing they are doing to have that boomless shape. You’re getting every bit of wind with no waste. Those boats are engineered to the hilt, I can’t wait to see what they do next year. I’m going to watch some videos later, thanks for the rabbit hole!

The race I have been following is the Vendee Globe. The website is so good. I highly recommend!

Vendee global is amazing! I feel like it’s the closest thing to a pure “all rounder” sailing - solo sailors, robust and well-engineered boats that are just smashing it every condition and loving ayvoace as well. I’m subscribed to their updates on YouTube.

So as to the madness of the americas cup - if you look at the sails they each have two wide counter coloured bands on them. when doing boat testing they use upwards facing LIDAR on both sides of the boat to calculate the best sail shape, live, and adjust accordingly. I feel a bit odd about that, I think trimming is one of the fine arts of sailing and to see it automated out is a bit sad. But if you’re doing 45 knots on foils, I guess the fewer jobs the better.

Interesting, is sail fabric thicker or easier to cut than like clothing fabric?

Also it’s interesting to see so many people who do different jobs online, I met someone the other month who lived in a boat during the FL hurricanes.

It can vary from thicker and heavier to lighter, and there are lots of different finishes as well so it can be quite stiff or supple. The cloth is made from polyester, or Dacron as it’s also known. We also use ripstop nylon for spinnakers. And then you have the laminate sails which can be made with Mylar and different fibers like carbon, Kevlar or dyneema.

Interesting, thanks for the information! In exchange I will give you information about my workplace.

At the grocery store when you have something you don’t want to buy just give it to the cashier, we have a dedicated system for someone to go put it back. don’t leave raw chicken sitting next to the candy, we can’t sell raw warm chicken.🙃

Oh man, that drives me nuts when I see that! I always try to find someone to give it to, you can’t put that back, you never know how long it’s been sitting there! Some people are so dense.

I’ve not worked in a grocery store but I did work at a butcher/deli. It was really fun, lovely people. Luckily it was small enough we didn’t have to deal with that!

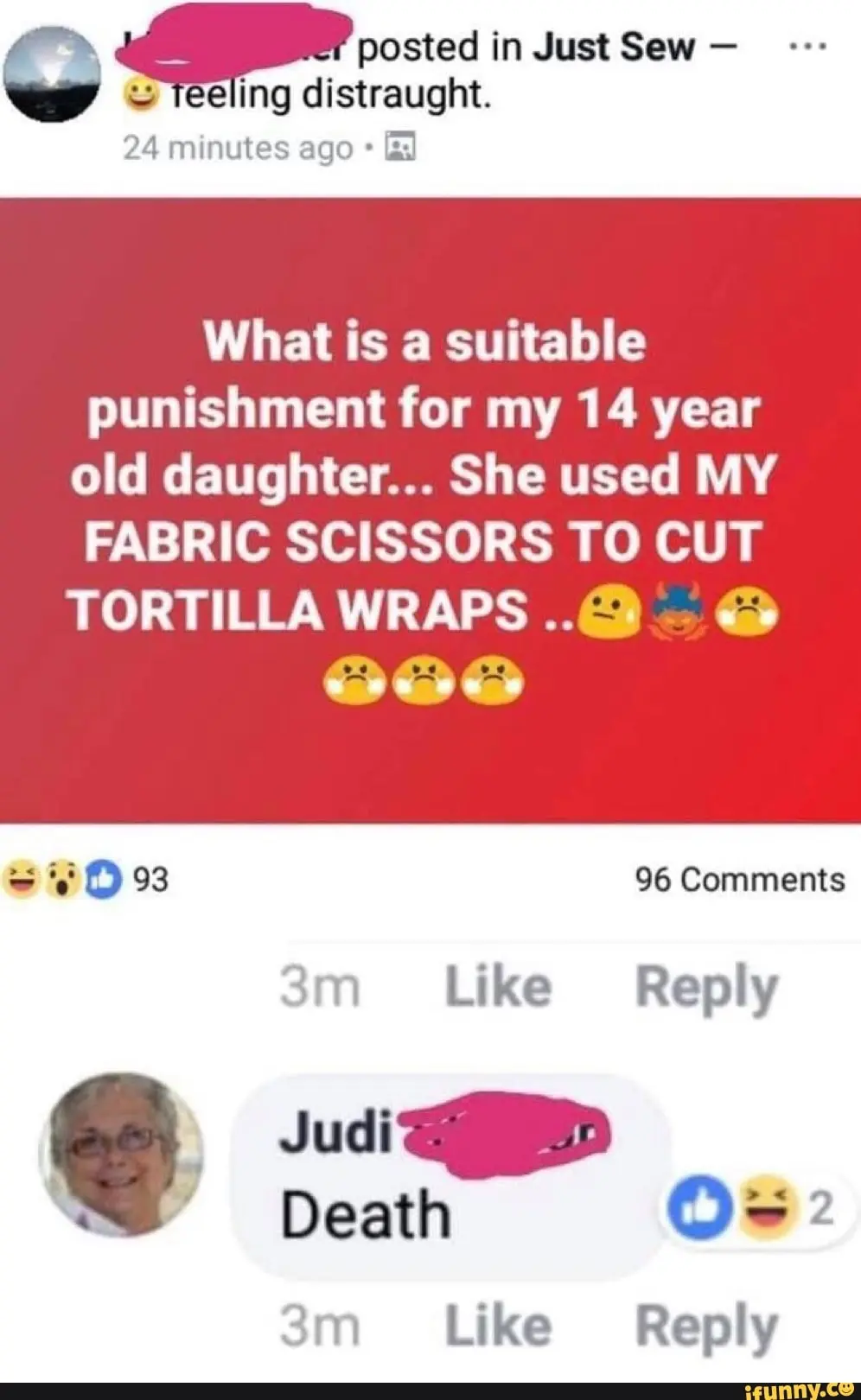

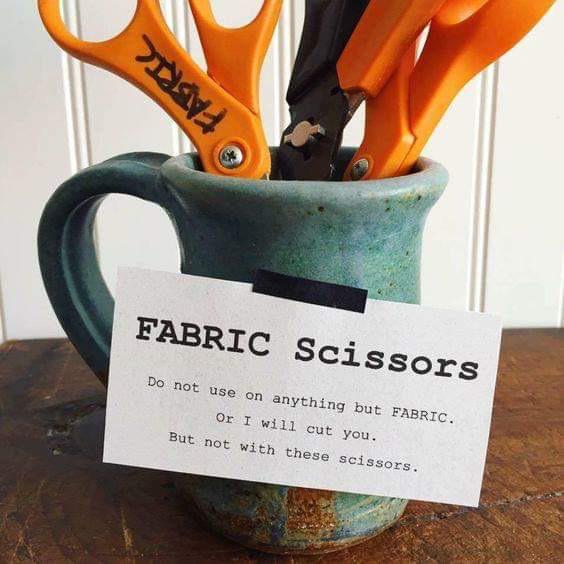

Whats the deal with fabric scissors? Do they break when used on other things?

fabric scissors need to be sharp to do their job effectively.

cutting other things, even paper, can (and will) dull the blades enough so they’re no longer suitable for their original intended task.

then when gramma, or whoever, wants to use ‘their scissors’ to cut some fabric, and they aren’t functioning properly… let’s just say it may not go well for the guilty party.

tl;dr: they’re no longer pure and must be replaced with new virgin scissors.

That’s when they become “stabbing scissors”!

Can’t you just sharpen them? Won’t fabric dull them? You can’t tell me that paper dulls scissors faster than fabrics.

I highly doubt using fabric scissors one time for cutting paper will do anything to them

You are hereby banned from the sewing room.

You think cutting through a tree won’t dull scissors? Fabric is made from plant fluff or hair.

More seriously - Yes you can sharpen them but many fabric stores no longer offer the service regularly. Some knife sharpeners will do it but others won’t. My scissors can be sent back to the maker to be sharpened but then I would be without my fabric scissors for weeks. If you do it yourself you will fail.

This is one of my favorite comments of all time. I have sent a screen shot to three different people that get pissed when I won’t let them use my shears.

had no idea about the level of complexity in sharpening scissors. TIL

They are more difficult than knives because they have to be sharpened so that they work as a set. If you screw it up, they no longer cut clean along the correct plane.

It’s not that bad, they’re single bevel so you’d have to try to sharpen the wrong side of the blade to fuck it up too badly

Any disruption of the interference fit between the contact or cutting faces can ruin scissors - it’s a lot like grinding a straight razor, but where you have incredibly strict angle requirements across a compound surface. You’re absolutely right though that the #1 mistake people make is to mess up the hollows by flat sharpening them like knives.

You’re highly wrong, then. Go get a straight razor and drag it through some paper, then see how nice it is to shave with. Fabric shears have surfaces honed to the same degree.

Does cutting fabric not dull the blades? It seems like a lot of fabrics should be tougher to cut through than paper?

Paper is made out of wood, the fibers are much harder than most sewing fabrics like cotton. It’s only easier to cut because it’s so stiff compared to fabric so even dull scissors can split it.

Yes, and you can sharpen them, it just takes time.

tl;dr: they’re no longer pure and must be replaced with new virgin scissors.

Damn that’s a horrible punishment. (I’m at least assuming if fabric scissors are only to be used on cutting fabric).

Fabric scissors just happen to be very good at cutting most things. I use mine to cut open packages, leather, plastics, and cloth! Just avoid cutting anything harder than the steel your scissors are made out of like metal, wires, and such. A quick hone will refresh the edges when you need it.

I was totally ignorant to the world of fiber crafts the first- and last- time my wife found me cutting up something with her sewing scissors.

Of course, that was before she became addicted to every fiber craft under the sun. Now I live in a house with several spinning wheels and a tapestry loom. This could be you too if you start crocheting. Take heed.

(I’m actually fine with it because she’s making me an Ernie sweater. I saw an Ernie costume on Halloween and I suddenly realized how much I wanted an Ernie sweater. So I asked and she immediately said okay. Yay!)

When she’s done the Ernie sweater could she make me a penguin one? Thanks

Thinking black sleeves on a white sweater, penguin on the white part of course, the cuffs are penguin foot yellow and the collar black as well.

The thing is, it’s pretty dang easy to sharpen scissors on a sharpening stone. Like, use em for everything! Go ham! Just sharpen them when they get dull.

So you know how when you cut something and the object was to hard for the scissors and the object turns sideways between the 2 blades and makes it so the scissors never function as well again? I’m way to good at doing that… Other than pulling my head out of my ass and using a different tool, any suggestions on how to fix those tools? My kitchen sheers are like that now after using them to prune my strawberries outside. (Clearly I need to have designated sheers/scissors for different things, but sometimes I’m just that idiot that thinks 1 hammer fits all jobs

Scissors work because the blades are tight against each other – there’s no gap between them when they’re cutting. When they “go sideways” it’s usually because the hinge is loose.

If they’re good quality scissors, you probably need to tighten the screw holding the blades together.

Yeah, old scissors used to have those, my kitchen sheers unfortunately do not, need to just get a nice pair and only use them for the kitchen.

You can still probably tighten them. Here’s a couple techniques. What you’re trying to do is squish the rivet holding the two halves together in order to tighten it back up.

Thanks, I’ll see if I can give that a try. I’ll be back to trying to cut down am oak tree with my kitchen sheers in no time! Haha

Use the right tool for the job. If you can’t figure out what the right tool is, you are the wrong tool.

Family is gathered around grandpa in this exact situation. He raises his head off the pillow and squints around the room.

That you, Bill?

Yes, dad, it’s me.

Is Carol here?

Yes, I’m here dad.

Jimmy? Sally? Are they here too?

Yes dad, the kids are here.

Is Walt here?

Yeah dad, I’m right here.

You’re all here?

Yes, we’re all here dad.

Everybody’s right here?

Yes, dad.Then why is the goddam kitchen light still on???

I am sliding gracefully into dad mode about thermostats because that is ancient technology and you should know better. Lights are all LEDs now and I even got the ones with batteries so they stay on in a blackout, so leaving them on charges them and is good, sort of.

Grampa still uses incandescents - he saw a meme about how you need a hazmat team if you break one o’ them newfangled bulbs and he’s not letting Obama jam those things down his throat!!!

Compact fluorescents are so last decade.

A cardinal sin.

on the one hand, other people should respect your shit.

On the other hand, you should know better. I’m usually against victim blaming, but if the scissors that are the easiest to find are your fancy expensive ones, then what did you expect.

The best way to protect your fabric scissors is to ensure that other scissors are more easily available to the idiots who’d wreck yours without a second thought. This also means keeping track of the shitty tools you never use because they exist purely to keep others away from your good shit.

I’ve been on the receiving end of this, and I’ve learned from it. I like candles, and have lived with potheads most of my adult life. Lighters go missing faster than I can buy them. Now i keep an electric lighter that can’t be used for smoking but can be used as a taser.

Well don’t leave them where they are accessible in cutting things that aren’t fabric.

Or maybe keep them with your fabric things.

Or maybe get a whetstone like your grandma did, grandma

Consumer grade whetstones are completely unsuitable for maintaining fabric shears. Maintaining a consistent bevel on stones that coarse is damn near impossible, and you’re most likely going to ruin the mate between the cutting faces beyond repair.

(“well I sharpened mine with an unoiled chunk of arkansas asphalt and they cut even better now”: no you didnt, you’re cutting with the burr, it won’t last, I hate you.)

Well don’t leave them where they are accessible in cutting things that aren’t fabric.

You have so never had a little girl Kelly in your life.